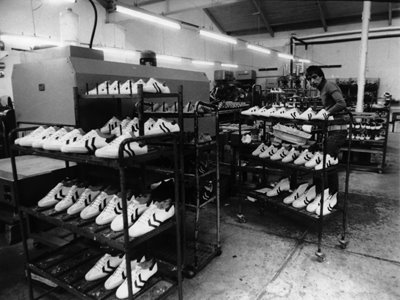

There's been some interest lately on the construction of football boots. Now, you can see what's on the inside!

Check the Read More link below for more pics and info.

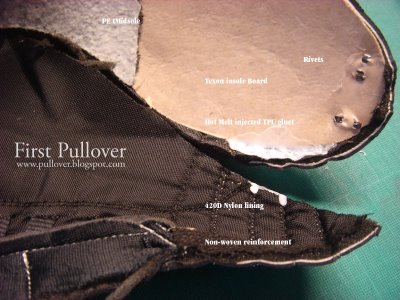

There is almost more that goes into a football boot on the inside than is visible on the outside. One of the most important things to assure good fit, comfort and performance (aside from the last) is the inner reinforcement and construction.

A properly constructed shoe, will hold its shape well, and be optimized to work with the material of the upper.

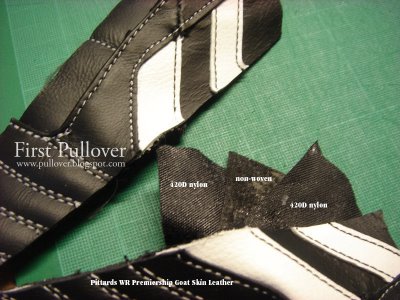

Although each style, or brand may be constructed slightly differently depending on materials, price and manufacturing method, most boots in general have the same 4 main components; upper material, foam, reinforcement, and foam.

Each material inside serves a different purpose. The upper material, as discussed earlier, here gives the overall touch, comfort and feeling of a boot.

The foam also adds some touch and feeling making the surface more soft and responsive. The non-woven material is used to help control the stretch of the upper material (all natural materials will have soem stretch because of the natrual grain structure), and the lining material also works in this way.

Labels: football, leather, materials, process, production