Here is the complete hummel Per Invitiation Only FW06 collection, with descriptions in english, for all those of you who couldnt read the exclusive first release post by Joachim over at 7inch.dk

The Per Invititation collection is the premium lifestyle footwear collection for hummel. Offered only to select sneaker and fashion stores, with limited distribution, only about 50 stores world wide.

Drawing inspiration from a variety of current and classic styles in sport and lifestyle, the PIO collection has been built with the concept "Jeg har Karakter" (I have Character) in mind. This concept mixes the unique personality of the hummel brand (chevrons and the bee) with innovative materials and colors designed for the street and the individual.

Click the Read More link below for more text and info.

HENNING

Football inspired lifestyle shoe mixing court and sport styles. Lace to toe style construction and a clean, simple, modern asethetic reflect the Danish design langauge and hummel sport history.

Original outsole with classic football cleat tread and rivets

Chrome pigskin lining

Embroidery asymmetrical hummel Bee logo (only on right foot)

Long vintage-style laces and extra set regular length laces included

Embroidery Bee logo on heel

Leather hummel Bee keychain included with each pair

NIELSEN

Redesign of heritage high cut handball shoe with contemporary, minimal Danish Design aesthetic. In 1848 the Danish sports administrator Holger Nielsen gave permission for a "handball game" to be played in Ortrup secondary school and promptly laid down the corresponding rules for it. One of the first appearances of the modern handball game.

Super soft nappa leather upper

Pig skin tongue lining

Extra set colored laces included with each pair

Classic original handball rubber outsole

Chevron heel webbing

JACOBSEN

Vulcanized high cut style mixing casual urban influence and Danish Modernism. Name inspired by influential Danish Architect/Designer Arne Jacobsen (1902-1971). Arne Jacobsen is well known for his classic, timeless, designs, including the Aarhus City Hall designed in 1938.

Chevron elastic forefoot strap

Chevron heel webbing

Holdsport Siden 1923 rubber heel logo

Laser Etch Bee tongue logo

Extra set colored laces included with each pair

Leather hummel Bee keychain included with each pair

Hummel branded outsole with tread and stitch

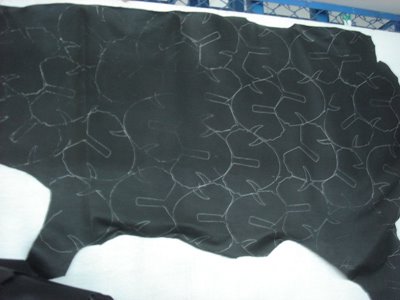

Laser etched monogram Bee/Chevron pattern on quarter (on White/Florescent Yellow colorway only)

**Jacobsen Camo uses the ultimate in performance leather. Constructed of Pittards WR Premiership Goat Skin Analine Leather, this material is the same material used by the UK SAS (Special Air Service) and Canadian Army for paratrooper and special forces gloves. This unique leather is completely abrasion resistant, sweat resistant, and water resistant while lightweight and soft to the touch. The Camo pattern, is produced using a patented CIG (Custom Image Generation) process, the ensures durability and performance.

more pics to come!