Once the corrections to the first model and technical drawing have been made, the mold maker in asia makes a revised tech drawing and model for my review.

Click the Read More link below for more pics and final correction to the 7.1 outsole model before the sample mold is made.

Overall, the second model much better represents the final outsole design. The width and proportion of the outsole bottom has been changed to be more slim at the waist, and in the heel area, while maximizing surface contact area for grip. you can see the difference in shape compared to the first model below.

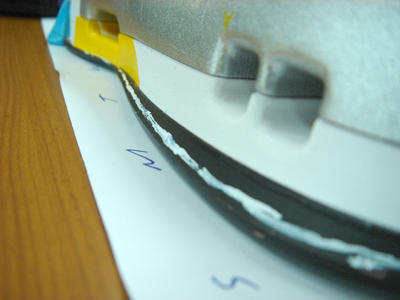

The second model corrected some of the assembly issues as previously mentioned with the stabilizer and outsole, but as shown here there was still a misunderstanding about the shape and assembly of the TPU stabilizer. The TPU stabilizer was intended to be a flat part assembled between the bottom midsole and outsole rubber. Similar to how it was created in the first model, but without the pegs. In communication with mold makers and technical people in asia, whose first language is not english, sometimes these things happen...

Here hou can clearly see the 3Di cushioning system. This cushioning system is designed to allow displacement or material into the holes from the top and bottom midsole to allow for good comfort and shock absorption. Unlike an air bag or other insert that uses a pressurized gas or liquid, this system cannot pop or leak under the extreme pressure of court performance of some very big players.

On the forefoot lateral side, there is an outrigger feature built into the rubber outsole. This outrigger helps give a physical feedback to the player who can then better control their movement in fast side-to-side lateral position changes. The effect actually is more psychological and cognitive than physical (its not big enough to stop you from rolling over), but works like a cat's whiskers help a cat to be aware of their location.

Corrected modified herringbone tread pattern for good grip on a court surface.

The waist features an airflow system created by the physical construction of the two CM EVA midsole parts. working through holes in the top midsole and a channel between the two parts, in combination with a special upper construction, the shoe is better allowed to breathe for better performance and comfort.

Labels: case study, design, development, hummel, indoor, innovation, outsole, process, production, sample, technology

0 Comments:

Post a Comment

<< Home